Basic components of "mototek" motors are designed and manufactured with a view to provide sturdy construction and accuracy. This results in optimum performance, reduced vibration, precision class tolerances, which reduces bearing noise and friction losses which in turn improves bearing life and efficiency and noise less working.

Body Frame : 63 to 100 frames are available in aluminum constructions as default. Gray Cast Iron bodies are also available on request. 112 to 280 frame motors are available in Gray Cast Iron Frame designed esthetically well and to withstand heavy shocks.

Terminal Box and Cable Entry : Gray Cast Iron frames has integrated and sufficiently large terminal box for batter protection from atmospheric dust and other particles. Aluminum frames has separate terminal boxes secured with proper rubber gasket to provide such protections. For cable entry proper sized PG threads are provided on the terminal boxes. B.S. Conduit, Metric and other threads can be provided in asked in advance. All the terminal boxes are secured with MS pressed covers which give good esthetics and protection as secured with rubber gasket.

End Covers : The flanges and end covers for 63 to 280 frames are made from Gray Cast Iron with integrated bearing housing ensuring lifelong wear resistance. For special application, motors with reduced flange and enlarged flanges are possible.

Rotor Shaft : Rotor shafts are normally manufactured with EN 8 D steel and are ground preciously. For specific application, Rotor Shaft with EN24 / EN31 or any other EN steel can be manufactured. Rotor with fusion SS shaft can be manufactured for chemical and food processing application.

Bearings, Lubrication and Sealing : "mototek" motors are normally comes with Single Raw Deep Groove Ball Bearings with rubber seals on both sides(2RS) up to 180 frame. This ensures IP55 protection as standard on the shafts. These bearings are pre lubricated ensuring proper lubrication and need not to be lubricated. Bigger frames are fitted bearing covers and are provided with re-lubrication on the end covers. In such case, the bearings are lubricated with high temperature grease of lithium Complex soap based type NLGI 2 and are protected with "V" ring or oil seals to safe guard the bearings from external dust.

Mounting : All the motor frames are available in Foot Mounting(B3), Flange Mounting (B5) and combination Foot+Flange Mounting (B35). Motor Frame up to 132 are available with Face Mounting (B14) and combination Foot +Face (B34). Motors with special mounting can be designed and manufactured to suit customer's requirements.

Noise Level : "mototek" motors are manufactured to perform silently - Feel the power of silence. The noise levels are much lower than the limits as per EN and IS standards.

Fan and Fan Cover : Aerodynamically designed fan and fan covers are used to provide sufficient cooling and yet minimum loading for better efficiency of the "mototek" motors. Thicker gauge of fan covers are used so the aerodynamic shape is maintained and provide maximum operator's safety by protecting accidental approach to the fan while under operation.

Balancing and Vibration : All rotating parts, mainly rotor with shaft are dynamically balanced on high performance NC balancing machine up to grade 2.5 for vibration free running. For high frequency or such specific requirement, rotors can be balanced up to grade 1.0 can be offered. This reflects on much lower vibration levels than specified in EN and IS standards.

Balancing of starting torque, Efficiency and slip are of major concern while designing "mototek" motors. The winding and insulating process and the material are also of prime concern. The design itself ensures the ease of winding as well as optimizing the performance.

Lamination : Laminations used are of high grade electrical steel and precisely stacked for better stacking factor to control losses and electrical losses.

Winding : Stators are wound with EC grade copper wires coated with Class "F" varnish for better insulation. Proper gauge for minimum losses ensures better efficiency.

Insulating Material : Insulating materials like sleevings and sandwich insulating papers of Class “F” and enough dielectric and mechanical strength. This allows withstanding higher temperature rise, wide range of voltage fluctuation and other electrical shocks.

Terminal Plate : The terminal plates are of DNC material for batter dielectric strength and having enough gaps to prevent inter phase shorting while energizing the "mototek" motors.

Supply Voltage and Frequency : As per standard Indian supply condition normally "mototek" motors are designed to operate at 415V + 10%, 50 Hz + 5%, 3 Phase OR 230V +10%, 50 Hz + 5%, 1 Phase with a conbined variation of voltage and frequency together at + 10%. As required for Frequency Inverter and for other parts of the world, "mototek" motors are available with various combinations of voltages from 24 V to 690V and frequency of 50 or 60Hz, for 3 phase supply and 110V and 50 or 60Hz for 1 Phase supply. High frequency motors are also available with jackated cooling.

Optional : "motoek" motors are available with thermister, thermal switch, space heaters, incremental or absolute encoder, resolver as required.

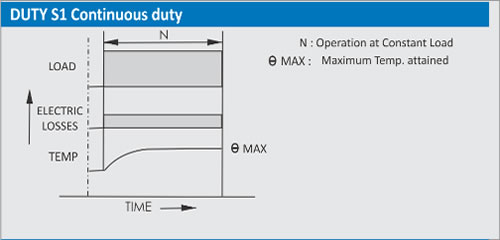

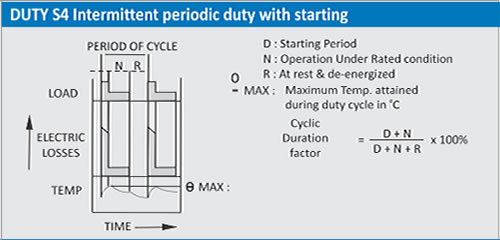

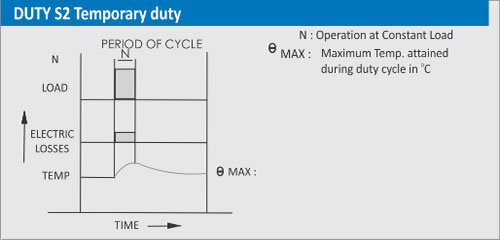

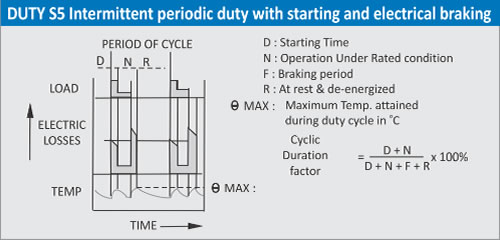

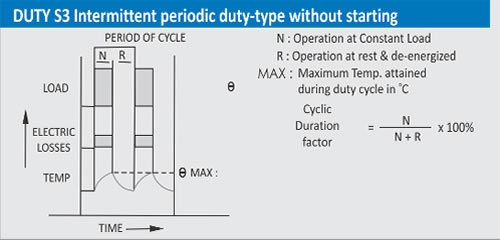

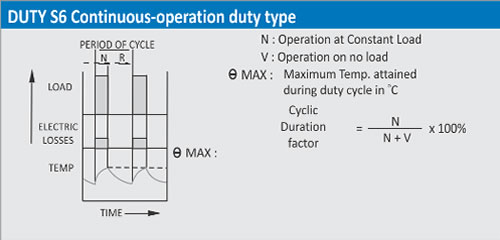

Duty : As a standard supply, all "mototek" motors are available with continuous duty cycle S1. However motors with duty cycle S2 to S6 are also manufactured against requirement. It is important to understand the duty cycle for which motor is to operated. The classification of duty cycle is shortly mentioned as under.

Temperature Rise and Insulation Class : With a latest technological development in insulating material, “mototek” motors are available with Insulation class “F” with a temperature rise restricated to class “B” as default. This will allow motor to withstand more frequent overloads or voltage and frequency variations. For traction and such other requirement, motors with class “H” are also manufactured against requirement.

| Temp. Ambient Permitted power as | 40 | 45 | 50 | 55 | 60 |

|---|---|---|---|---|---|

| % of rated power | 100% | 95% | 90% | 85% | 80% |

Derating Factor : The value of performance and ratings of “mototek” motors are at 40 C ambient temperature and up to 1000 meter MSL altitude. However same motors can be used for higher ambient temperature and altitude but it has to be derated as specified in the tables. If specified, motors with higher ambient temperature and altitude can be manufactured.

| Altitude above sea level In meters | 2000 | 3000 | 4000 |

|---|---|---|---|

| % output of Motor | 95 | 85 | 77 |

| Ambient temperature In * | 45 | 50 | 60 |

|---|---|---|---|

| % output of Motor | 98 | 96 | 90 |

Paint : All the casted components are shot/sand blasted and coated with epoxy primer to ensure better surface adhesion of paint and prevent the rusting. MS components are also cleaned with phosphating and coated with epoxy primer. The finished "mototek" motors are painted with RAL aluminum based paint which ensures better heat dissipation and lifelong paint protection. The Machines lamination - mainly rotor and the shaft extension are coated with rust preventer to protect them from rusting.